Sorghum is one of the most rapidly growing species on the planet. In the U.S. Midwest and south it grows higher than two metres in as little as 110 days. Sorghum has a low water requirement and can provide two harvests per year. It is grown in semi-arid regions around the world for many uses. Sorghum’s high lignocellulose content results in strong, durable fibreboard panel with better insulation and with more attractive aesthetic qualities than many traditional building materials

It is hard to imagine anything exciting about wallboard.

After all, it has been many years since much of the world settled on some type of wall paneling because of its ease of installation.

Of course, it wasn’t always that easy to finish walls, and many decades ago there was really only one choice. Stud walls (2 x 4s in those days) were strapped with rough material known as lath, which was covered with a lime-based plaster using hand tools. Sometimes the plaster was reinforced with horsehair.

At some point, a clever person decided to replace the lath with sheet material, similar to current drywall, and install plaster over the whole board. Then an even smarter person said, “hey, let’s put plaster only on the joints, saving time and materials.” And so for many years, that’s the way it has been.

The sheet material we know as drywall is also called sheetroc or gyproc, after the gypsum from which it is made. Drywall can be made thinner and thicker and can be bent around curves.

It can also be an effective fire retardant barrier. The wood within the wall will eventually burn, but drywall slows the process enough to allow occupants to escape the building.

Drywall also serves to reduce noise transfer using double layers, which is particularly useful in buildings with common walls such as duplexes and apartments.

Regular drywall doesn’t handle moisture well because the paper layers will mould.

A board in which the paper is impregnated with an oil can be used in high humidity situations. This product is called greenboard, not because it is more environmentally friendly but because it has a green coloured paper layer.

Cement board is used instead of drywall where moisture is really a potential problem, such as around a shower. It uses Portland cement instead of gypsum.

Drywall is considered a material of mass. It can slowly absorb heat for later release, similar to stone, concrete and masonry products. This enables excess heat in a building to be moderated during the heat of the day and available for release later when the building starts to cool.

Home builders sometimes place discarded pieces of drywall in the interior wall cavities before they are enclosed to add mass and heat absorption capacity to their walls.

So beyond all those good characteristics, what can possibly be new about wallboards?

There is lightweight drywall-gyproc that is handy, particularly for ceilings where installers bear the full brunt of the weight of the panels.

The lightweight panels are 30 percent lighter and still meet all fire and impact resistance and thermal barrier requirements.

Drywall is not always gyproc. A new panel material, already popular in Europe and Asia, is coming to North America. It is made of magnesium oxide rather gypsum.

MgO does not support mould, is insect and moisture resistant and has good impact resistance. It can be used on exterior walls with a coating and has good fire resistance.

It is considered “greener” because it is an abundant naturally occurring material and is less energy-intensive than gyproc to manufacture. It is also free of toxins such as formaldehyde, silica, asbestos, heavy metals and organic compounds.

Synthetic gypsum is created from a byproduct of flue-gas desulfurization in coal-fired power plants called fly ash. It seems to be a clever way to use what would otherwise be a waste product, but there are concerns about heavy metal contamination, such as mercury.

This may not be a problem when it’s used in wallboard, but drywall represents 15 percent of construction waste, which means there is concern that leaching of the material will occur when it ends up in the landfill.

The U.S. Environmental Protection Agency has said it is comfortable with the product, but others are not so sure. Let’s just say that the jury is still out as to whether it is an advancement.

Air Renew, a new drywall product from CertainTeed, claims an ability to clean the interior air of formaldehyde, which is found in common modern products such as glue, paint, cleaning products, cosmetics, furniture, cabinetry, flooring and carpets.

It is a known carcinogen that can also cause headaches, respiratory problems, depression and other health issues.

The company claims Air Renew may absorb and secure formaldehyde for as long as 75 years. It also says the formaldehyde is inert, even in a landfill situation.

Drywall is certainly the most common material used for wallboard, but there are others. Some are even bio-based, which means they are made of natural materials other than wood.

Many of the products have been straw based and mostly from China, but Chlorofill of San Diego has developed an interior panel called DurahStyle, which is based on drought-resistant sorghum and manufactured in Missouri.

Sorghum is a grass-like crop that grows three to four metres high in only four months with little rain. It’s seed is used for sugar (molasses-like syrup or ethanol) or grain (gluten-free flour or animal feed).

Its use in wallboard prevents the stalks from being burned and provides additional income for farmers. As well, being straw rather than wood means reduced pressure on beleaguered forests.

Sorghum has long fibres, which is important for manufacturing. When layered, they make a strong and durable panel that is formaldehyde-free and made from a renewable resource.

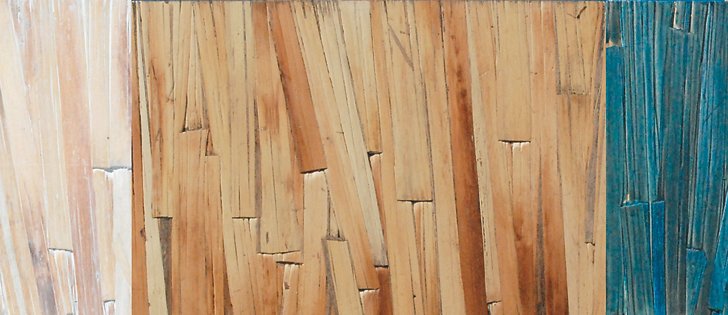

The manufacturer claims DurahStyle will not chip, has low water absorption and will not warp or de-form. The panels can accept paint or stain and have a unique look, more like bamboo, so they are likely to be used for architectural purposes.

If you want to finally vanquish that old 1960s basement rec room characterized by ugly and dark faux wood grain with vertical grooves, you now have some newer interesting alternatives. Some of them are even green.

By Will Oddie: a renewable energy, sustainable building consultant with a lifetime interest in energy conservation. To contact Oddie, send e-mail to energyfield@producer.com.

Source: Advances change composition, expand uses for wallboard – The Western Producer.

Related articles